Production line

BKHD-100

Rotary type hydro band manufacturing machine

- Product Features

- Product

- Machine specification

-

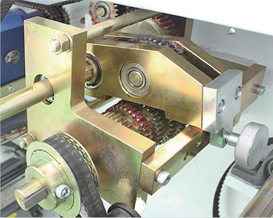

- Change gearbox

- 40 bands produced by one machine

-

- Position control device

- Control of gauze and wrapping paper cutting position through button operation during high-speed production

-

- touch screen

- All information at a glance

Speed adjustment and tension adjustment for each part

-

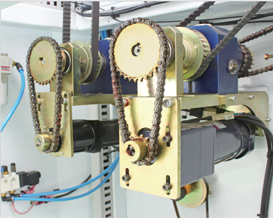

- Safety drive system

- In case of emergency, the entire equipment can be stopped with the emergency stop button

- Block type that can be easily replaced within 5-10 minutes when changing mold gear

- The special product can be produced by installing the eye mark recognizer on the molding part and the packaging part (optional)

- Partial repair is possible as it consists of separate parts for each part

- Sensors are attached to each part, so there is an automatic stop function when the supply of the fabric is not easy to minimize the fabric loss

- Plate type main body for easy repair and one person per work

| BKHD-100 |

|

|---|

| BKHD-100 | ||

|---|---|---|

| Fabric | Width | 75mm or less |

| Material | PVC, cotton, polyurethane film, urethane, non-woven fabric, hydrocolloid, hydroform | |

| Gauze | Width | 15~35mm |

| Material | Gauze, hydrocolloid, hydroform | |

| Packing | Sealing | Cold sealing / hot sealing (optional) |

| Material | Paper, PE film / aluminum (optional) | |

| IMARK | Option | |

| BKHD-100 | |

|---|---|

| Production speed | 50~120pcs/min (100x100mm / based on hot sealing) |

| Power | 10KW |

| Size | 3,700L x 1,400H x 2,000W |

| Main Porter | 5HP, 10:1, inverter speed control type, PLC type touch screen(Order specification) |

| Weight | 1,500kg |

| Voltage | 220V/380V, 60/50Hz (Order specification) |

맨위로