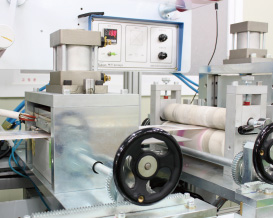

Production line

BKHS-150

Step type hydrocolloid spot maker

- Product Features

- Product

- Machine specification

-

- Manual adjuster

- The position of the wrapping paper and gauze can be adjusted manually

-

- Touch Screen

- All information at a glance Speed, distance adjustment

-

- Packing regulator

- Control of wrapping paper speed and sealing temperature

-

- Safety drive system

- In case of emergency, the entire equipment can be stopped by the emergency stop button

- Block type that can be easily replaced within 5-10 minutes when changing mold gear

- The special product can be produced by installing the eye mark recognizer on the molding part and the packaging part (optional)

- Partial repair is possible as it consists of separate parts for each part

- Sensors are attached to each part, so there is an automatic stop function when the supply of the fabric is not easy to minimize the fabric loss

- Plate type main body for easy repair and one person per work

| BKHS-150 |

|

|---|

| BKHS-150 | ||

|---|---|---|

| Fabric | Width | 20~150mm |

| Material | Hydrocolloid | |

| Packing | Sealing | Cold sealing / Hot sealing |

| Material | Paper, PE film / aluminum (optional) | |

| IMARK | Option | |

| BKHS-150 | |

|---|---|

| Production speed | 20~60pcs/min |

| Power | 10KW |

| Size | 3,000L x 700H x 1,000W |

| Main Porter | 2HP, Servo control moter type, PLC type Touch Screen(Order specification) |

| Weight | 1,300kg |

| Voltage | 220V/380V, 60/50Hz (Order specification) |

맨위로